Coal and Community

A very large number of mines, drifts and shafts have been worked on the northern flank of the Rhigos Mountain, in northern Glamorgan, over a period of over two hundred years. Since the nineteenth century various collieries there operated under the name ‘Tower’, a reference to a folly constructed by the famous ironworking Crawshay family on nearby Hirwaun Common in 1848.

William Williams began producing housecoal, manufacturing coal and fireclay from a drift mine named Tower Graig in 1864. In 1878 Tower Colliery was opened by the Bute Trustees. From the Inspector of Mines list of 1896, Tower Graig Colliery was discontinued. Also from the same list, Tower Colliery, owned by the Marquess of Bute, was producing steam coal with a workforce of 420 men. In 1918 there were 679 men employed at Tower.

The extant Tower Colliery – located near Hirwaun, at the top of the Cynon Valley – commenced with the driving of the No.3 Drift in 1920. In 1935, it came under the ownership of the Powell Duffryn Group, the largest coal company in both south Wales and the UK. The shaft known as Tower No.4 was sunk from 1941 to 1944, to a depth of 165 yards. It was used for transporting manpower only. In 1945 there were 1,045 men working at Tower.

On 1 January 1947, with the nationalisation of the British coal industry, Tower became owned by the National Coal Board (NCB). Tower’s No.3 New Drift was driven in 1958–9, connecting to the No.4 workings and becoming the ventilation for the colliery. It was used solely for conveying coal and materials.

An explosion of firedamp occurred at the colliery on 13 April 1962, killing nine men and injuring a further nine. This was the worst accident in Tower’s history.

Tower Colliery in the aftermath of the 1962 disaster (Photograph from National Union of Mineworkers (South Wales Area))

In 1964 Tower was linked underground with Fernhill Colliery, located in the upper Rhondda Fawr valley the other side of the Rhigos. Tower-Fernhill comprised a single unit employing 860 men and producing around 250,000 tons of semi-anthracite per year. This coal was brought to the surface at Tower and then taken by overland conveyor to the nearby coal preparation plant, where it was washed and blended. This conveyor, installed in 1964, was three quarters of a mile long – the longest of its kind in south Wales. The coal was used for domestic heating and for manufacture of the smokeless fuel ‘Phurnacite’. The Fernhill side was closed completely in 1980.

By the late 1970s, mining operations at Tower encompassed an area of around four square miles and took coal from the Five Feet and Nine Feet seams at a maximum subterranean depth of 457 metres. This ‘take’ was split by a series of geological faults, which displaced the seams in places by distances of up to 50 metres vertically. There were more than ten miles of underground roadways, incorporating more than seven miles of high-speed belt conveyors. Nevertheless, Tower Colliery was also the last mine in south Wales to use pit ponies, a practice which seems to have been phased out by the mid-1980s.

During the 1984–5 strike, Tower was famously one of the several south Wales collieries which did not see a single strikebreaker for the duration of the year-long dispute.

After the strike, in 1986 Tower received investment of £5 million in new double telescopic power roof supports in the V29 coal face in the Five/Seven Feet seam, where anthracite was up to 10ft thick. This face also received a powerful 500hp power-loading machine with two cutting drums. It was anticipated that the face would have an output of at least 1,200 tonnes per day. It was also in this year that the coal was brought through the mountain from Mardy Colliery to Tower.

In 1994, British Coal closed the colliery because it thought it would be uneconomical to keep it working. However, a successful bid for the colliery was made by a buy-out group formed from 239 members of its workforce, who each pooled their £8,000 redundancy payments to constitute the £2 million buy-out fund. Tower thus became the first colliery in British history to be owned and run by its own workers. In 1995, they produced 450,000 tonnes of high-grade anthracite, making over £4 million in pre-tax profit.

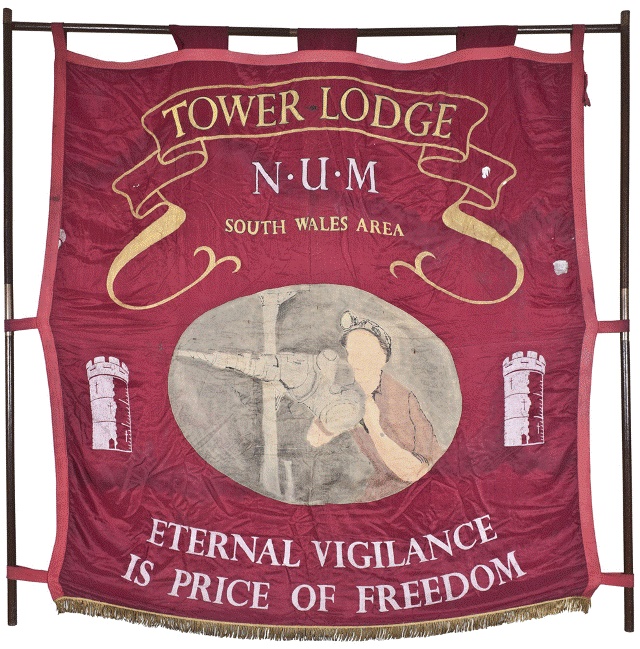

Tower Union Banner (Photograph from National Union of Mineworkers (South Wales Area))

Tower, the last deep mine in Wales, eventually closed on 25 January 2008, having exhausted its geological reserves.

This profile was written towards the beginning of our project, further material about Prince of Wales colliery is available at our exhibtion website.

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-2024/Diane-Spencer-(Teaser-image).jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-18-19/220325-Engineers_teach_thumbail.jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-2024/240509-Menopause-Research-Resized.jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images/Maria-Serria-(teaser-image).jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-2024/241014-Cyber4ME-Project-Resized.jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-2024/240315-Research-Resized.jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-2024/BDA-group-photo.jpg)