Innovation project clocks up first century of clients

A project supporting SMEs (Small to Medium Enterprises) to develop new products has just clocked up its first century of clients with 100 businesses now on board.

The University of Wolverhampton’s Innovative Project Support Service (iPSS) is part funded by the European Regional Development Fund and supports SMEs through the early stages of developing a new product or process, aiming to bring it closer to market.

Working with partners at Aston University and Birmingham City University, the project offers support delivered free of charge by experienced consultants with specialist knowledge of the client business’s sector and development needs.

Support includes product design, engineering analysis, market research, intellectual property advice, electronics development, commercial reviews, implementation of sensor technologies and new product development & planning.

Professor Andrew Pollard, Project Director said: “The project gives companies an introduction to working in collaboration with the University, and that initial engagement often grows into a bigger partnership”.

“We are aiming to assist over 200 companies by March 2019 so the level of support available is significant to businesses. The project also includes funded support for a number of research collaborations. These are designed to support eligible research projects carried out by University researchers in collaboration with SME companies, and we’ve got high aims to grow and develop our research impact through this.”

For further information please visit the iPSS webpage. Alternatively, please contact Project Manager, Mike Shields on 01902 321105

The following case study detailing the support given to Lichfield based Advanced Innovative Engineering Ltd serves to demonstrate the scope of assistance available:

Overview

Advanced Innovative Engineering Ltd (AIE) based in Lichfield design and manufacture Wankel rotary engines. These engines have a wide range of applications including aviation, marine and automotive.

Challenge

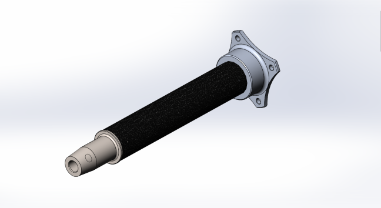

Many of the engines AIE produce are for the aviation UAV market. Mass is a key concern and they are frequently being requested by customers to reduce the mass of their assemblies. Most of AIE’s componentry is produced from aluminium, either machined from billet or from castings. AIE considered the next step in their product evolution to be the introduction of carbon composite materials. AIE commissioned consultant James Jones CEng to conduct an IPSS project in order to research the feasibility of introducing carbon composites into certain components. The prop shaft was the first part to be identified.

Solution

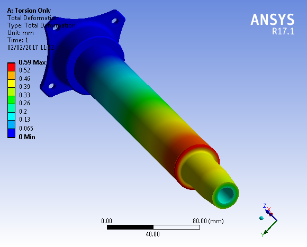

James began by researching the previous use of composite prop shafts and found that the technology has been successfully used for automotive prop shafts. It was clear that not only was the mass saving an advantage, but the increased stiffness could be utilised in order to create longer, one-piece shafts where complex two-piece shafts had been previously used. James continued to research theory and produced detailed design calculations which proved very useful. Designs were produced based on these calculations and confirmatory FEA analysis performed.

Results

A great many factors needed to be considered for a successful design. These included: torsional stiffness and resonance, bending stiffness and whirling resonance, fatigue strain, buckling resistance, methods of assembly and, of course, mass. It was found that a 20% reduction in the mass of the shaft is possible for this like for like carbon composite based redesign. The IPSS project is now set to progress into a research collaboration with the University of Wolverhampton, leading to prototype production and manufacture.

About the consultant

James Jones graduated from the University of Wolverhampton with a first class BEng degree in mechanical engineering. He is a chartered mechanical engineer with experience in the automotive braking and crane design industries. James has worked with companies including Morgan cars, Siemens, Jacobs, Balfour Beatty and those within the nuclear industry.

ENDS

For more information please contact the Media Relations Office on 01902 32 2736 or 01902 518647.

Date Issued: 17th August 2017

For more information please contact the Corporate Communications Team.

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-2024/240328-Varsity-Line-Up-Resized.jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-18-19/220325-Engineers_teach_thumbail.jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-2024/240423-Additive-Research-Centre-Launched.jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-2024/240320-Uzbekistan-Resized.jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-2024/240229-The-Link-Resized.jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-2024/240416-Abi-Dare-Resized.jpg)